They call them leadership boards. Anyone going to visit any production facility within Hearthside Food Solutions (HFS)’s network — and there are 20 of them — will immediately come across them prior to taking a tour of the facility.

The boards quickly provide managers, employees and visitors an immediate overview of how the plant is performing by measuring what HFS calls the Top 5 Key Performance Indicators (KPIs): Safety, quality, service, cost and culture. It’s a 24-hour scorecard that no one can hide from since objectives and results are color-coded. Green means on target, red indicates issues have cropped up.

“It’s all about transparency,” says Dwayne Hughes, HFS’s senior vice president of supply chain. “Anyone walking through a Hearthside plant can see how the facility is running.”

It’s also about a long-term plan to make every HFS plant a world-class operation, the underlying strategy behind the company’s Hearthside Performance System (HPS). Developed by Hughes upon joining Hearthside at its very founding — the company was formed in 2009 upon acquiring the assets of Roskam Baking Co. — HPS has proven critical in fulfilling the company’s role as a dedicated contract manufacturer.

Given that HFS’s mission is to be “the preferred bakery, snack, cereal and customized solution provider to premier food companies,” having world-class manufacturing capabilities makes that goal tenable.

As Hughes explains, “We don’t own our own brands, we don’t own formulas. All we own is our trust, and our fast and flexible manufacturing assets. We need to be on the cutting edge of innovation as well as remain flexible.”

And that’s what Hearthside has done successfully within a very short period. When Rich Scalise, the company’s founder and chairman, created HFS five years ago with the help of Wind Point Partners of Chicago, he did so knowing the benefits and challenges of co-manufacturing.

As the former president of Ralcorp Frozen Bakery Products and president and coo of ConAgra’s Refrigerated Foods Division, Scalise was more than familiar with contract manufacturers. By offering premier branded customers speed, flexibility and more value, Scalise was certain that HFS could quickly make an impact in the marketplace.

Through timely acquisitions, HFS has grown from a company doing $200 million in sales with four plants and 2,000 employees to the country’s largest food contract manufacturer doing $1.2 billion in sales, 20 plants and 7,500 employees.

In addition to producing cookies, crackers and snacks, HFS has become the largest co-manufacturer of snack bars in North America. It has six snack bar facilities, three in Grand Rapids, Mich., one in McComb, Ohio, one in London, Ky., and one in Michigan City, Ind.

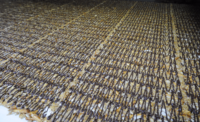

With regards to cold-forming or granola-type bars, the company has five high-capacity bar lines, all of which are located in Grand Rapids, producing 800,000 bars per shift. All plants have a SQF III certification and are AIB-rated.

“The strategy behind HPS is to become world-class,” Hughes explains. “And that takes about five to seven years. And we have two plants, the H1 facility and our plant in Michigan City, Ind., that are very good, very close to attaining that level.”

KPIs, Hughes adds, provide managers and employees with key metrics on how the plant is performing based on standards developed by the industry and in accordance with government regulations. With an extensive background in food manufacturing — Hughes worked for Quaker, Nabisco, ConAgra and Ralcorp — the supply chain executive combined the best manufacturing practices and systems from each and used them in the development of HPS.

Thus, be it Five-S, a workplace organization method devised by the Japanese that stands for sort, set, shine, standardize and systemize, lean manufacturing or RCO (Rapid Changeover), HPS uses metrics to instill ownership and accountability, a sense of urgency, discipline and continuous improvement.

“Take safety, for example,” he says. “We determine how we’re doing by looking at the OSHA (Office of Safety and Hazard Administration) incident rate, which the agency determines by examining our plant records. An incident rate less than 1.0 is considered world class.”

Moreover, unlike safety, which has a long-term tracking time, there are KPIs that provide real-time updates, such as performance boards that track bar production on an hourly basis. Using industrial engineering studies, performance standards are set and results recorded.

Supervisors and managers, working in conjunction with line operators, track output on a whiteboard. The process drives “a sense of urgency,” Hughes says.

“I’ve worked in plants where such processes are automated,” he explains. “But I noticed that when you automate the process, it takes the human factor out of it. By going to a manual system, you involve people. And the white boards make it really simple to make changes. In an instance, you have a 24-hour picture of how the plant is running.”

Here, too, the green-and-red designations apply. But the red designation isn’t designed to be a scarlet letter. Rather, it’s meant to be a problem-solving tool. Thus, when a performance index is marked in red, there’s an accompanying notation stating what the issue is, and what was done to resolve it.

As expected, there are daily reviews and response meetings held by each shift as well as operator hand-offs between shifts. The point behind the green and red indicators is not punishment, but problem-solving.

“Our goal is for each plant to show improvement every year,” Hughes says. Nonetheless, progress isn’t uniform for every plant.

“We have what we call lead, mirror and shadow plants,” he says. “The lead plants get all our resources and my attention since they’re close to attaining world-class status. In mirror plants, we send employees to the lead plants to train them there and take those best practices to implement at their sites. Our shadow plants undergo training on-site to meet performance goals.”

Providing managers, supervisors and employees the right resources and tools, of course, facilitates the continuous improvement journey. That’s where the HPS toolbox comes in. Tools, such as a “play books” which designate the number of people and the kinds of skills needed for a specific line, or a maintenance flexibility matrix, which highlights skill levels of maintenance employees, help determine the right number of people for the task at hand as well as pinpoint the need for cross training.

Then there’s HFS’s ultimate tool box: $35 to $50 million annually in capital expenditures.

In 2011, the company invested in a new bar line from PTL, one that met its specific criteria involving RCO, such as easier-to-clean elements in the line as well as an ultrasonic cutter.

As Hughes explained, traditional slitters used in cold slab bar forming needed to be sharpened every shift. By investing in an ultrasonic cutter from PTL, the blade doesn’t have to be sharpened until 10-12 shifts of production. Moreover, this particular ultrasonic blade actually kicks the cut bars forward, thereby “indexing” the bars in alignment for enrobing, another benefit.

Hughes looks to gradually introduce this innovation across all the bar lines. As he explains, “We’re looking at the best vendor, the best tool and the best equipment, which will allows us to standardize across the entire company.”

This attention to continuous improvement dovetails with HFS’s involvement with its customers, most of which are some of the largest consumer packaged goods players in the country.

As Hughes says, despite HFS’s rapid growth — it was ranked as one of the fastest growing companies by Inc. Magazine while Crain’s Chicago Business estimated that HFS posted a 36 percent gain in revenues in 2013 — “There’s no time to take a breather.”

“We have to stay in tune with the industry,” he continues. “We need to continue to grow with our customers, continue to be flexible and to provide innovation.”

In addition to being proactive in manufacturing, which means scouring equipment shows such as interpack and Pack Expo for innovations, the company takes a very active role in product development, monitoring trends within the $5.7-billion bar category.

“We purchase Nielsen data and look at trends,” Hughes says. “We also talk to our customers, to our vendors. What we’re finding is that bars are becoming much more complex. Some are totally enrobed, bottom-enrobed, specific inclusions viewable on top of the bar. Lately, there have been several reformulations in order to produce healthier bars, bars with more protein, even gluten-free bars.”

Interestingly, increased complexity in bar production actually benefits HFS, Hughes points out. Whenever products require more changeovers, allergen control, ingredient control, the nation’s major brands prefer to turn over manufacturing to someone else, someone like HFS, he says

To further demonstrate its capabilities to its customers, the company also stages innovation shows annually. There, HFS showcases products that it’s developed that can be produced on its equipment. They are customer-specific and reflect market insights. Although Hughes couldn’t detail specifics, he did note that in the last two years, several concepts have actually been launched by HFS’s customers as new products.

“When the company was formed in 2009, we didn’t have an R&D department, Hughes says. “But in talking to our customers, we found out that’s what they wanted.” As evidenced by the new product launches, it’s been a great success.

That success can be measured not only by HFS’s growth rate, but by its operating capacity, which averages 85 percent across its manufacturing network. Continued growth will necessitate more production capacity. Current projections foresee the bar category growing to $8.3 billion in five years. Expect HFS to grow accordingly.

At-a-Glance

Hearthside Food Solutions

Headquarters: Downers Grove, Ill.

Sales: $1.2 billion

Products: Bars, snacks/components, cookies, crackers, granolas and cereals

Plants: 20 (bar plants – 6)

Output: 2 billion-plus lbs. of co-manufacturing capacity (3 billion bars annually)

Management: Richard Scalise, chairman, ceo and co-founder; Scott Edgcomb, cfo; Bob Scalia, senior vice president, strategy and business development; Dwayne Hughes, senior vice president – supply chain; and Steve England, senior vice president – human resources.