Innovation, continuous improvement, and market-oriented development characterize Hosokawa Bepex worldwide as a powerful producer of systems, encompassing the Ter Braak, Bepex-Hutt and Kreuter brands, for the confectionery and bakery industry.

Production capacity and price are no longer the primary factors used to make purchasing decisions. Strict hygienic guidelines and the pressure to reduce cleaning and changeover times with regards to machine design have become extremely important. That’s why Hosokawa Bepex, in cooperation with its customers and end users, have started a new line of hygienically designed machinery that sets new standards with regards to components, material and overall design that simplifies cleaning, changeovers, and maintenance. The abbreviation HD for “hygienic design” characterizes our latest generation of equipment.

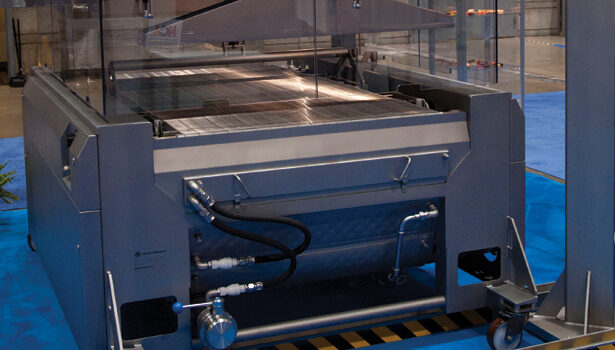

Our latest innovation in this field is the new Hygienic Design EnroberChocoat Premium HD. This revolutionary new enrober is constructed so that the components and parts have been dramatically reduced. Both the parts and assembly units can therefore be dismantled easily and subsequently cleaned within a very short time.

In addition, all the parts are made of solid stainless steel and the wire mesh belt can easily be removed as ‘one part’ without cutting the wire, enabling customers to swiftly and hygienically clean this part of the enrober. The in-feed and discharge knife edge are made in a special plastic material that is also designed to be removed swiftly and easily.

Another development that makes the Chocoat Premium HD unique is the frame, which is designed as “unibody” with large openings where the rods and shafts are located. Once again the shafts are also made of stainless steel and can be easily removed from the enrober body. The mass pump, valves and machine feet are now labelled with the EHEDG certification and the unit can be wheeled very easily so it can be removed for further cleaning and maintenance.

Continuous welding for the mass trough, return plate and lateral machine walls all come as standard and are now all frame-mounted. As a result, all the surface seams are continuously welded together, thereby offering the maximum hygiene for the whole system.

The new hygienic design enrober will be seen for the first time at ProSweets in Cologne in January 2013 and follows the successful launch of our existing range of (HD) equipment, namely: the Hygienic Design Bottomer, the High Efficiency Cooling Tunnel and the Fanning/Spreading Conveyor.

At ProSweets, visit us at Hall 10.1, booth C040 or go to www.bepexhosokawa.com