A looming cocoa shortage, changing requirements for the end product and improved energy efficiency — these are the challenges that the cocoa and chocolate processing industry is face. As a result, these challenges affect not only producers but also suppliers to the industry.

At ProSweets 2013, Bühler, as one of the leading technology partners for the cocoa and chocolate industry, will exhibit its latest solutions for the entire value chain — from cocoa roasting to the moulded chocolate product.

Highlights include a new cocoa drum roaster, Tornado RSX, and new solutions for compound production with EasyComp. Additional items from the flexible moulding line ChocoStar Compact and much more will be exhibited at Bühler’s booth at ProSweets in January 2013.

Cocoa processing

Bühler’s industry solutions for the cocoa industry start with a raw fermented cocoa bean. For a perfect end product, it is important to process the cocoa carefully to ensure that an optimal quality and behavior can be achieved. Bühler Barth is constantly developing its equipment further in order to achieve the desired product behavior and quality while retaining the traditional strengths of its existing solutions.

The latest innovation by Bühler Barth is the two-in-one drum roaster Tornado RSX. The new cocoa nibs roaster combines convective and conductive roasting technologies in a single roasting cycle that allows optimal recipe differentiation based on end-product quality. The hot air that streams through the cocoa nibs can be used for faster drying, saving process energy as well as improving roasting notes. The conductive process enables the traditional roasting flavor to develop and can be combined with the new process possibility of convective roasting. Thanks to this new process design, the roasting time of cocoa nibs can be significantly reduced (+/-20%) with no impact on flavor and with reduced energy consumption.

Compound mass production

Due to the increasing cocoa shortage, the compound production segment is becoming more and more important for chocolate manufacturers. At present, Bühler is well known for its efficient and reliable production equipment, starting at throughputs of 500 kg/h. At ProSweets 2013, Bühler will introduce its new compound solution, Easycomp, which is suitable for production capacities of between 100 and 300 kg/h. With Easycomp, Bühler will now also be able to serve the needs of small- to mid-sized producers. The new solution was specifically developed for compound chocolate applications. However, thanks to the modular and flexible design, even conching can be integrated, meaning real chocolate can also be produced with this innovative system.

High efficiency and perfect shape

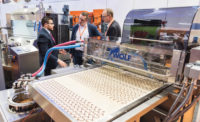

There is almost no limit to the varieties and shapes of moulded chocolate products. As a result of this moulding, it must be possible to apply lines flexibly. The ChocoStar Compact from Bühler Bindler fulfills exactly this requirement. The modular design ensures highest product flexibility and allows the line to be expanded easily. Another important feature of the ChocoStar Compact is the increased efficiency of the entire moulding line, including the depositing process.

The groundbreaking FlexiNozzle is a new depositing nozzle from Bühler Bindler. Thanks to its flexible valves, FlexiNozzle guarantees depositing accuracy and clear tail breaking. As a result, the moulds are less polluted and there are fewer damaged products. Furthermore, cleaning and service times can also be reduced. To avoid any loose pieces falling into the moulds, in the unlikely event of a breakage, the valves can be detected using a standard metal detector.

At ProSweets, visit us at Hall 10.1, booth B050/C059 or go to www.buhlergroup.com