At ProSweets, Theegarten-Pactec will be exhibiting its FPC5 horizontal flowpack machine. During the trade fair, the modular wrapping machine will package chocolate-coated wafer bars. The unit is also designed for moulded and chocolate-coated products, coated wafers, biscuits, cereals and other food and non-food products that require similar product handling demands in flow packing.

Visitors to the booth will also have the opportunity to experience a secondary packaging solution for display cartons in action; the adjacent LoeschPack booth will feature a LRK cartoner that will take over the chocolate bars and package them.

This cooperation marks the first time that Theegarten-Pactec and LoeschPack will be showcasing their abilities together as system providers for confectionery wrapping. The expertise both companies command comprises all the packaging processes involved, from feeding and wrapping all the way through to cartoning. Jointly conducted projects and successfully implemented solutions for internationally active confectionery manufacturers have repeatedly underscored the high quality understanding that characterizes both partners. Moreover, their international positioning is either comparable or complementary. The cooperation leverages the synergies of both machine portfolios from which joint customers benefit.

Coinciding with the trade fair, Theegarten-Pactec is introducing a novelty for the formats handled by the showcased FPC5. The FPC5/280 model variant extends the wrapping material area to widths of up to 280 mm, and product format widths of up to 120 mm. This enables producers to flowpack chocolate products in the typical 100-gram format and larger formats. Over and beyond Europe and North America, chocolate bars are particularly relevant for developing countries in which the middle classes are now beginning to show rising demand for such confectionery items. In view of the climatic conditions in India and Asian countries, the use of silver foil and conventional paper wrapping is hardly an advisable option.

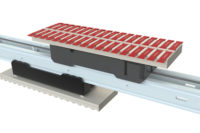

Thanks to its modular concept, the FPC5 can also be retrofitted to extended requirements at a later stage. The five main modules consist of the product and the wrapping material feeding unit, the sealing unit, the product discharge and the control unit and electrical system. There are various options available for each of these main modules, such as low contact, vacuum -upported synchronization ensuring maximum product protection or print image precision splicing achieving a minimized number of ejected products during automatic roll changing.

The MCH is the second major exhibit. As a wrapping machine for various wrapping styles, it belongs to the Theegarten-Pactec medium performance range. With regard to the especially delicate jelly products handled by the machine showcased at the trade fair, the speed of 1,000 products per minute is a peak performance that continues to represent a unique position on the market. In addition to double-twist wrapping, the MCH offers three additional types of wrapping: protected twist, side twist and metallic foil wrapping.

At ProSweets, visit us at Hall 10.1, booth G038/H039 or go to www.theegarten-pactec.com