Sollich KG, the leading manufacturer of special machinery for the confectionery industry, will present numerous innovations at this year’s ProSweets in Cologne.

The worldwide successfully operating Turbotemper Top tempering range has been expanded to include two additional sizes for 100 kg/h and 200 kg/h tempering capacity, thus addressing smaller volumes and capacities. The Turbotemper Top type TT 100 B and TT 200 B are equipped with a reheating reservoir tank and a feed pump. The compact design guarantees flexible handling while maintaining a superior tempering quality of the chocolate, even at low capacity applications.

Another unit that will be on display is the Turbotemper Top TT 2200 in “D“-version with an integrated Tempergraph for a continuous quality control and built-in “Teach-In“ function for a constant, automatically controlled temper index.

For the manual control of the temper index, the well-known fully automatic Tempermeter Typ E5 is available in the latest design. The integrated touch-screen panel simplifies the operation and provides additional options for data analysis and transfer.

Furthermore, Sollich will exhibit the new mini enrobing machine type MinicoaterTMC 420, which has a built-in tempering system and was introduced at interpack 2011. The machine will be running with chocolate during the exhibition. It is available in 320 and 420 mm working widths.

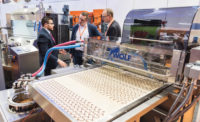

In addition, the Enromat M5-1300 MAGNUM, a high duty enrober with 2,400 mm length and 1,300 mm belt width, will be shown. An external tempering machine type Turbotemper Top feeds the enrobing machine via the Sollich circulation tempering system — a natural combination allowing exact enrobing weights with a tolerance of +/- 0.1%, thus ensuring the utmost tempering and enrobing quality even at very high working speeds.

The Enromat M5 series is available in belt widths ranging from 820 mm up to 2,600 mm and represents the leading technology in chocolate enrobing that is used worldwide for challenging applications.

In addition to a special “CIP“-version, which can be washed and dried automatically in accordance with a patented procedure, Sollich also implements customized solutions designed for special application purposes.

Moreover, Sollich will present the Cluster Former CF, which has been used for decades for the production of round, rectangular or oval clusters — little piles of chopped nuts, cereals, dried fruits, brittle bits etc. with fat binder (compound or real chocolate). The clusters are formed volumetrically and are deposited by individual pistons onto the cooling conveyor.

The Cluster Former is available in a working width from 320 mm up to 1,300 mm and can easily be wheeled into place over a continuous cooling conveyor. Thanks to its hygienic design, which facilitates quick cleaning, and an interchangeable metering drum, maximum flexibility is guaranteed for the Cluster Former.

Furthermore, Sollich is a competent partner for all applications regarding enrobing with fondant or caramel, bar and praline forming systems, depositing of fat and sugar masses, sprinkling and decorating as well as for the production of soft and hard candy products.

At ProSweets, visit us in Hall 10.1, booth B020/C029 or go to www.sollich.com.